Siemens Energy – Biofuels in Gas Turbines, Exclusive Interview.

Siemens Energy is a global team of more than 91,000 dedicated employees. They’re responsible for meeting the growing energy demand while ensuring our climate is protected. They keep the best of their 150-year legacy and push the boundaries of what is possible. Siemens Energy strives for sustainability in their decarbonization journey, innovation centered on future technologies, and transformation among future focused offerings, portfolio and mindset. Siemens Energy is committed to making sustainable, reliable and affordable energy possible.

Can gas turbines today operate on biofuels?

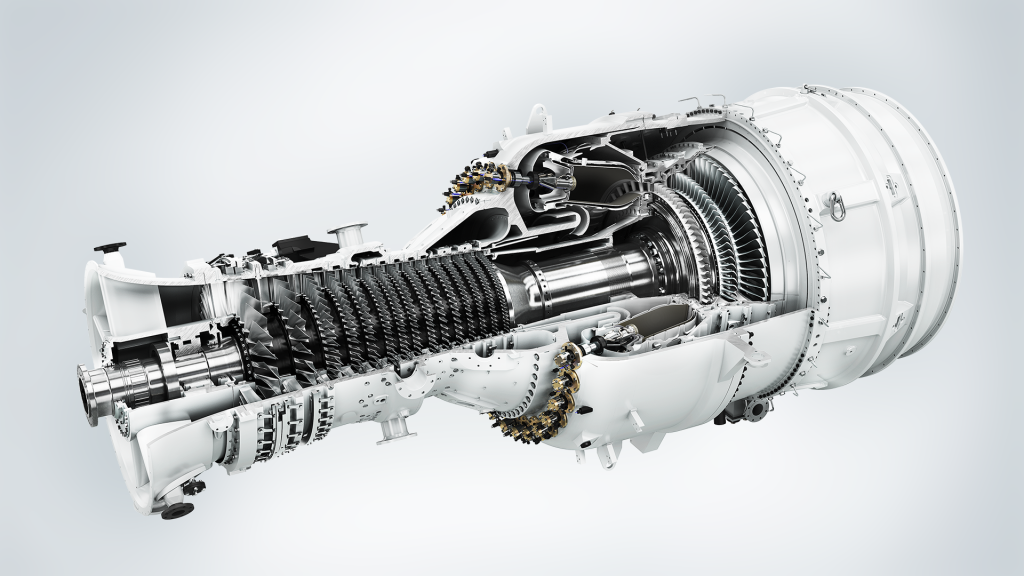

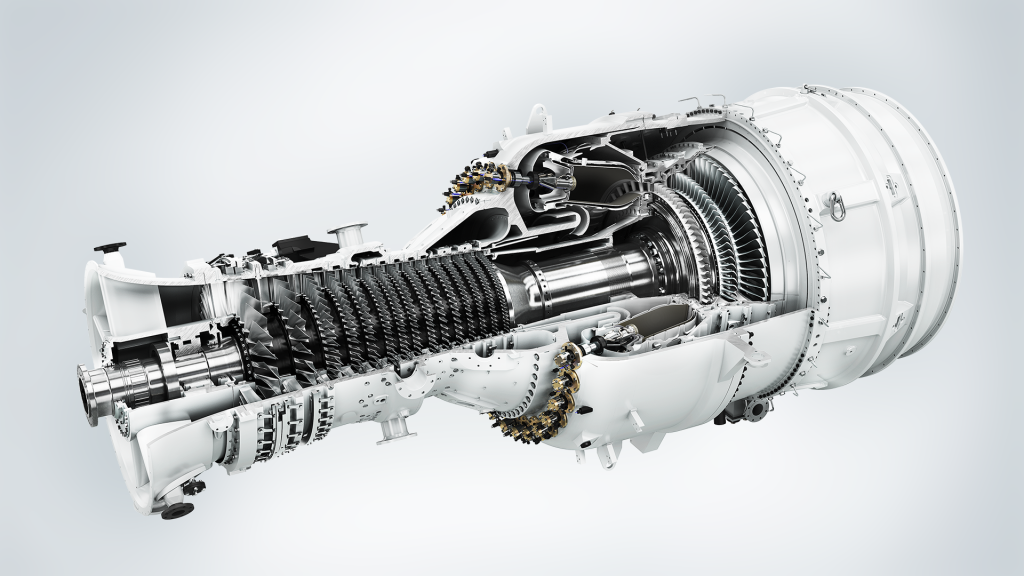

Biofuels like biogas, biodiesel, bio-methanol and bioethanol are beside hydrogen important decarbonized fuels and part of Siemens Energy gas turbine R&D roadmap. We perform tests both at our own facilities and together with Universities/Research Institutes and with customers. As an example, we have a collaboration agreement with Göteborg Energi, owned by and providing energy to the city of Gothenburg in Sweden, which includes testing of biofuels in their SGT-800 gas turbines at Rya Combined Heat and Power Plant.

During November 2021, as part of a program supported by the Swedish Energy Agency, tests of gas turbine operation on biodiesel (HVO-100) were carried out. HVO-100 has a high potential as a future biofuel, and it is also very similar to next generation bio-diesel such as Fischer-Tropsch Diesel. Through the tests, we validated that HVO-100 is a suitable fuel for our medium gas turbines using third generation DLE (Dry Low Emission) burners. Our third generation DLE burners are continuously developed for wider fuel flexibility, where AM (Additive Manufacturing) is a key component for the next generation of burners. Further fuel flexibility testing, including hydrogen, biodiesel and methanol, of both existing and newly developed burners is scheduled during 2022. We have also recently sold another SGT-800 gas turbine to a back-up power plant in Stockholm, Sweden that will operate on HVO.

🔥 What about we co-host a webinar? Let's educate, captivate, and convert the biofuels economy!

Biofuels Central is the global go-to online magazine for the biofuel market, we can help you host impactful webinars that become a global reference on your topic and are an evergreen source of leads. Click here to request more details

So what about availability?

Biofuels are available already today but have great scale up potential with emerging technologies as for example biomass gasification which can be used to produce both gaseous and liquid biofuels. Furthermore, these new advanced technologies will be able to produce fuel from forest and agriculture waste, enabling a shift towards production of advanced 2nd generation biofuels at a large scale.

Many of these biomass wastes are not suitable at all for conventional biomass fired plants, and represent a large unexploited potential, but can in the future be efficiently upgraded and utilized with the help of gasification. The new advanced biofuels which are produced from waste and residues are more sustainable and have also significant cost advantages compared with traditional, 1st generation biofuels produced from crops, and which compete with food production.

So, what is most promising – biogas or bio liquids?

We see both biogas and liquid biofuels as important for gas turbines going forward. Liquid biofuels are suitable for back up or peaking applications, especially where no gas infrastructure is in place, like in remote applications and island grids, while biogas is suitable where existing gas infrastructure is in place and can be blended with natural gas in a transitional phase. Flexible mixing of hydrogen with biogas also strengthens the gas turbine competitiveness as it allows the installed gas turbines to operate also when hydrogen is expensive.

Liquid biofuels could also be a backup fuel to natural gas, hydrogen or biogas. That way, the storage capacity for the gas can be dimensioned for the normal operational profile, while more easily stored liquid biofuel can be available for more unusual events and provide an alternative in cases of interruption of gaseous fuel supply. Flexible Combined Heat and Power plants with gas turbines can both provide efficiencies over 90% and the needed flexibility to the electricity sector. Another advantage with gas turbine plants is that they can be located in proximity to larger cities and through this provide district heating or back up also in times when transmission of renewable electricity to the cities is insufficient or not working properly.

But aren’t biofuels also emitting CO2 when burnt?

Yes, they are, but unlike fossil fuels they are coming from a renewable feedstock and are part of the natural cycle, a closed loop circulation of CO2 as long as you grow as much biomass as you harvest. Smaller CO2 emissions may occur when transport and processing of biomass is done with conventional fossil energy, while the combustion of biomass itself is considered carbon neutral as long as the biomass itself is from a sustainable source.

The EU taxonomy stipulates that biofuels can be either sustainable or unsustainable depending on how they are produced and where the biomass is coming from. If fuels are derived from sustainable production and not obtained from land which has a high biodiversity or a high carbon stock, and at the same time provide more than 80% GHG saving compared to fossil alternatives, they are considered sustainable. Advanced production technologies are both more efficient and can scale up the use of waste and residues for fuel production, both beneficial factors from a green house gas perspective.

Will competition with other sectors, like the transport sector, not limit the available volumes?

Yes, and the same goes for other low carbon fuel besides biofuels, such as hydrogen and e-fuels. That’s why we want to have the possibility to burn many different fuels in our gas turbines to enable our customer to choose depending on availability and price. And what we already see happening is that many gas turbines operational profiles are changing along with the amount of solar and wind entering the energy system. With gas turbines operating more flexibly while fewer hours in total, the fuels quantities available to the power sector can be sufficient.

Is biofuels also suitable for combined heat and power plants?

With limited amounts of biofuels available for heat and power generation, Combined Heat and Power (CHP) plants with gas turbines and efficiencies even above 90% is a good choice. By utilizing biofuels and hydrogen in a gas turbine CHP plant, it can play an important role providing fossil free flexibility on the electricity market at the same time as it produces heat. By adding a thermal energy storage solution to the CHP plant, electricity production and heat supply can be uncoupled, enabling a more flexible operational profile.

This means that the generation of electricity can be varied to follow fluctuating power prices resulting from variable solar and wind power production patterns. For district heating and cooling applications, thermal storage may consist of relatively simple water tanks, which can provide storage system benefits to the energy system at a fraction of battery system costs. As it allows the CHP plant to participate in the supply of ancillary grid services, it can deliver additional value to the plant operator as well as contribute to a reliable and well-functioning energy system.

Johan Leirnes, Sustainability Strategist within the Industrial Gas Turbine segment at Siemens Energy

You can get in touch with Siemens Energy sending an email to:

Copyright © Biofuels Central. All Rights Reserved.

Cover Photo Credit – With new technology, Göteborg Energi and Siemens Energy have successfully run a gas turbine in the Rya CHP plant with liquid biofuel instead of natural gas.

READ the latest news shaping the biofuels market at Biofuels Central